Piezoelectric dispensing products

Providing custom products and services for developing small volume dispensing applications

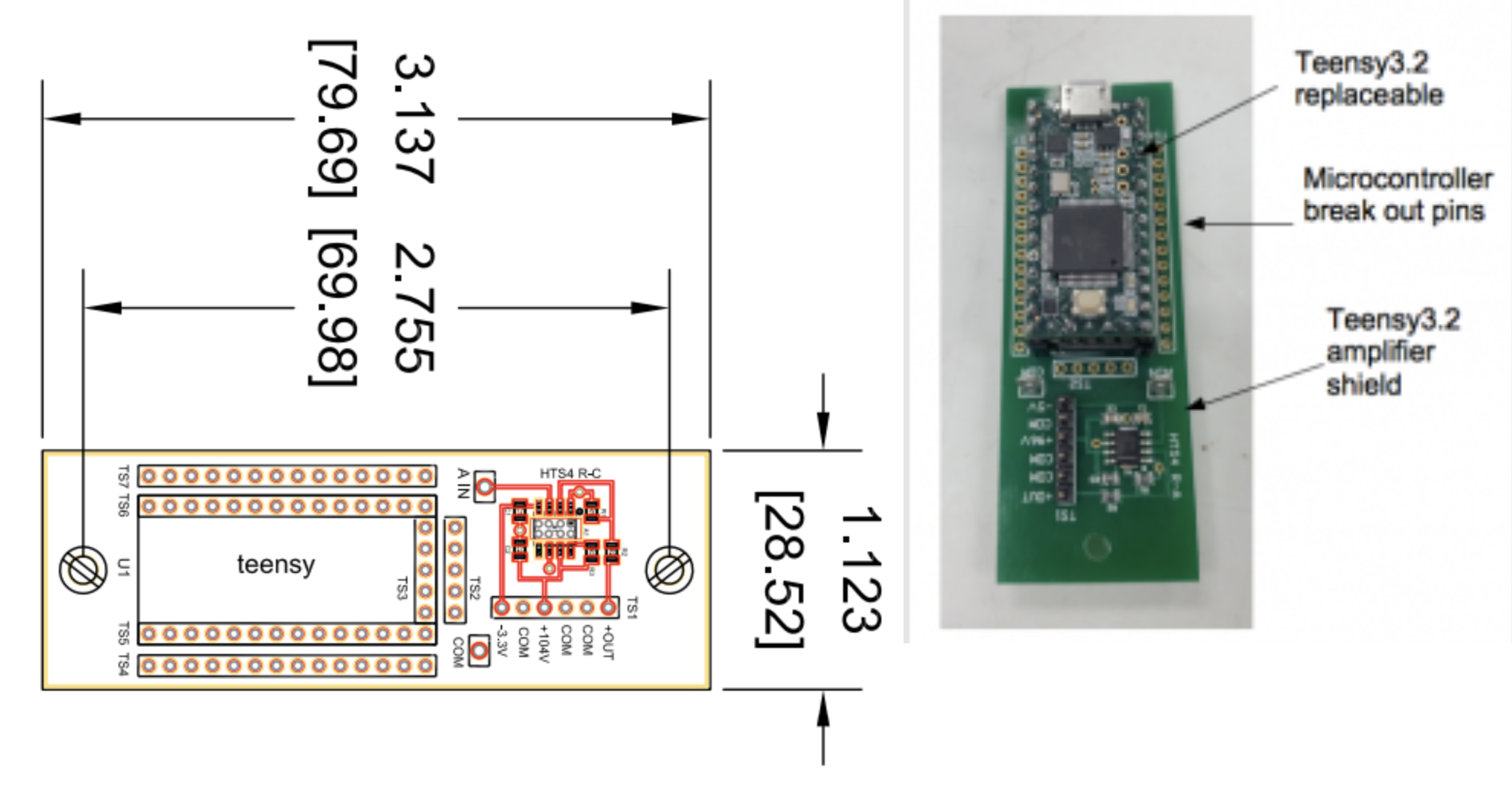

High-Voltage Amplifier Shield

Up to 100V output, compatible with Teensy 3.2 and Arduino microcontrollers.

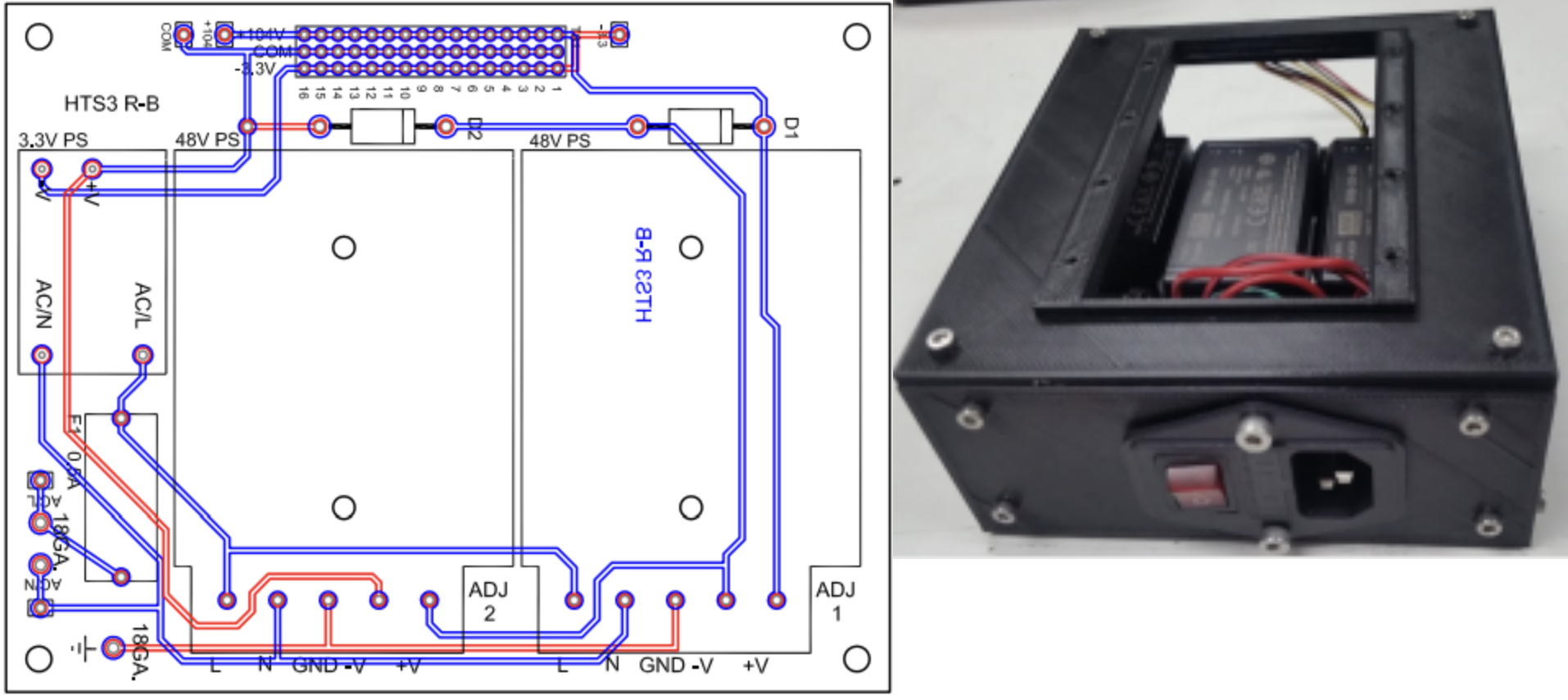

Amplifier Power Supply

Power up to 16 amplifer shields.

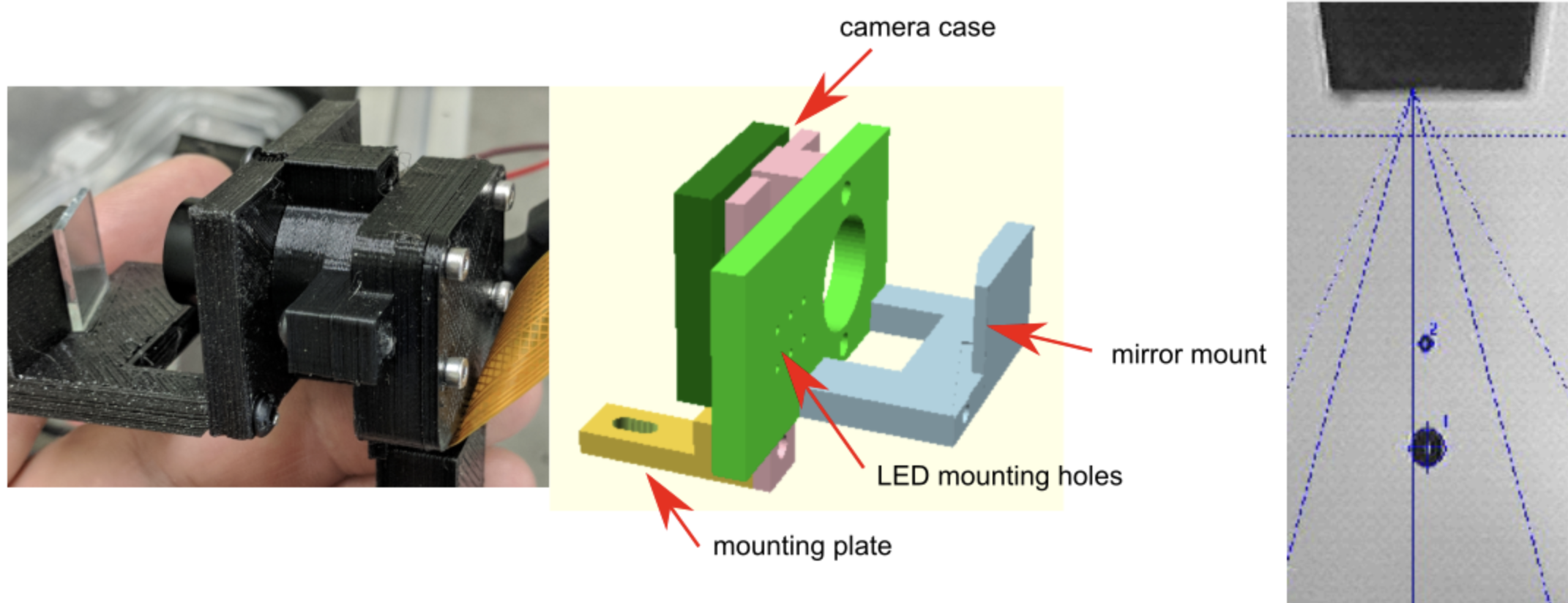

Stroboscope

Visualizing droplets in flight using an arducam focusing camera the led flashes within microsecond time delay from actuation pulse.